Truck engines deteriorate at a faster rate than other vehicle engines. They have higher horsepower, heavier weight and design, and higher frequency vibrations.

The ability to detect these issues for businesses operating in the transport space, therefore, needs to focus on not ‘if’, but ‘when’.

Fleet managers have an urgent need to identify engine issues, fast—preferably in real time—so that they can be rectified as quickly as possible. The lack of action has the most obvious repercussion – the increased likelihood of accidents, which in turn increases the chance of injury or death, as well as countless costs to the business. Unfortunately, this is currently a documented area of weakness for the transport industry, and others. Haworth’s 2000 study cited road accidents as the most common form of work-related deaths, as well as work-related accident and injury in Australia.

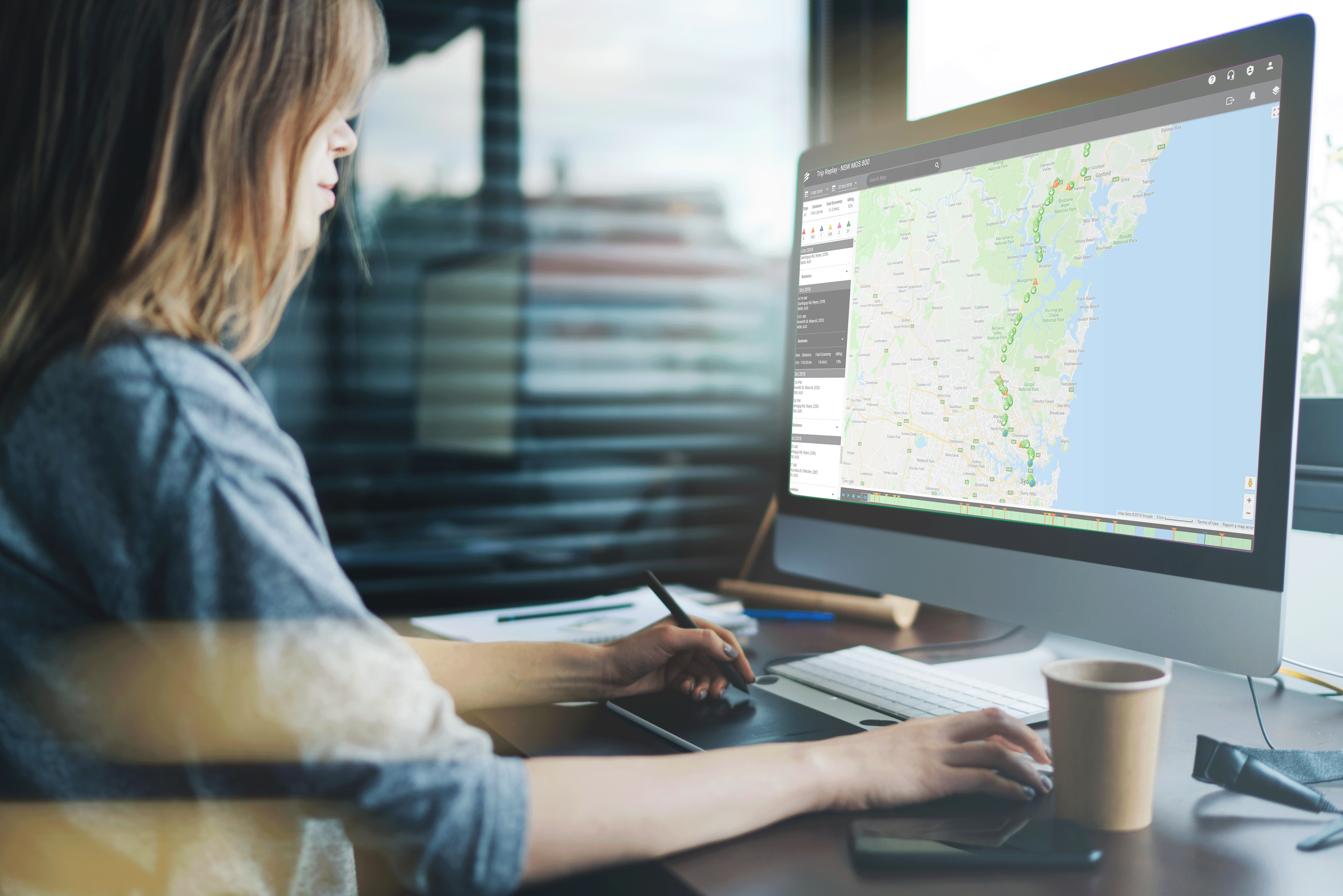

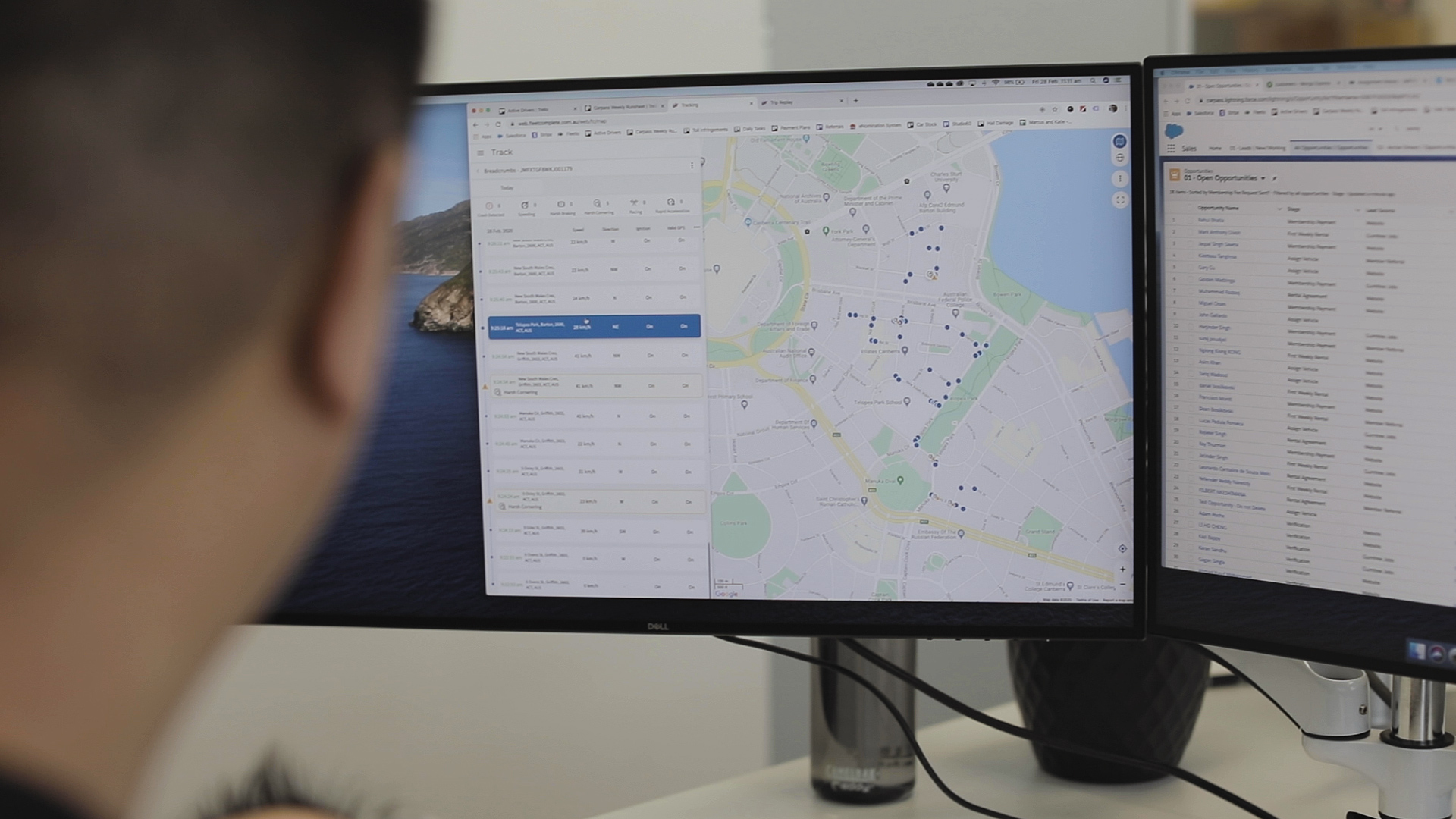

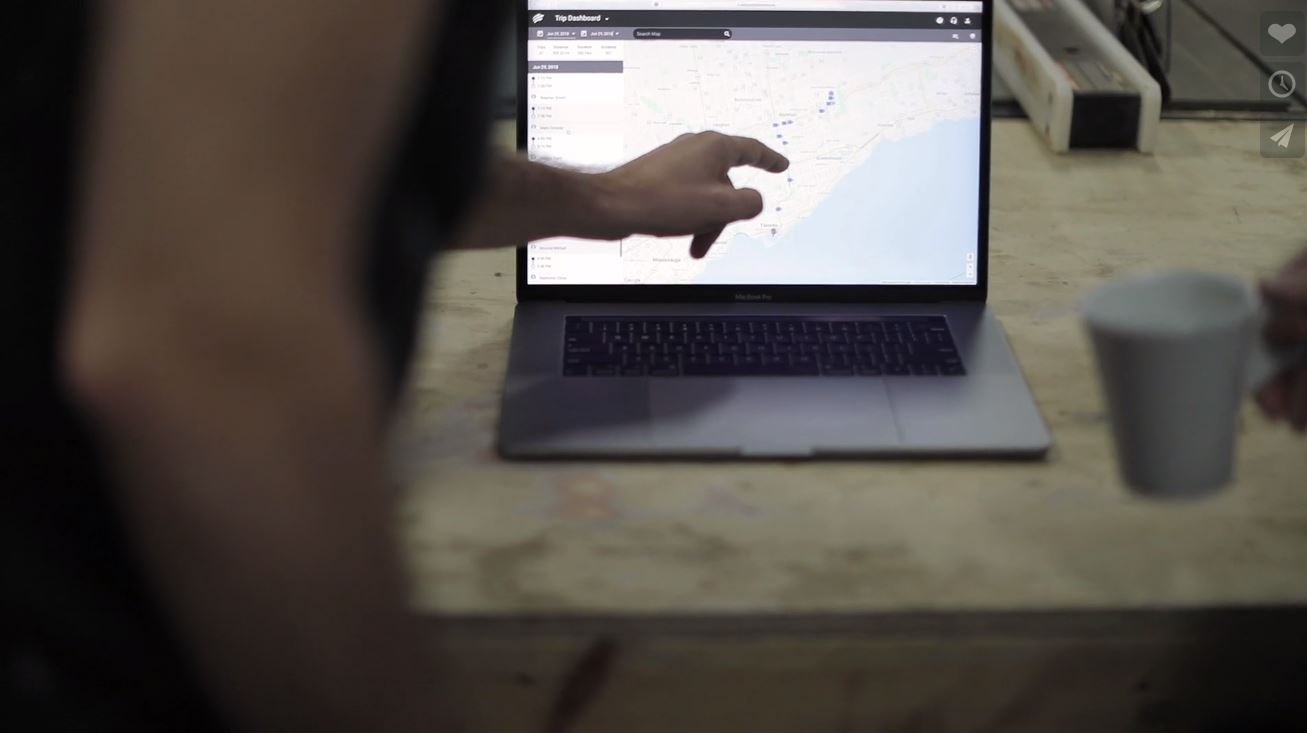

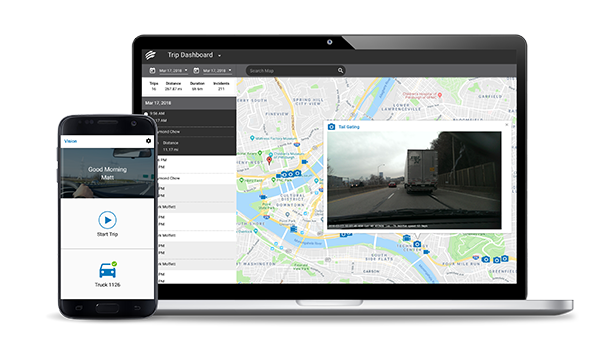

Fleet management software offers the solution to this worrying trend, and is becoming a growing necessity for businesses striving for improved driver safety via minimisation of engine-related accidents. By selecting a robust system that enables high-level reporting, tracking, and monitoring, you’ll be able to drive down engine-related problems and instead focus on improving day-to-day operations.

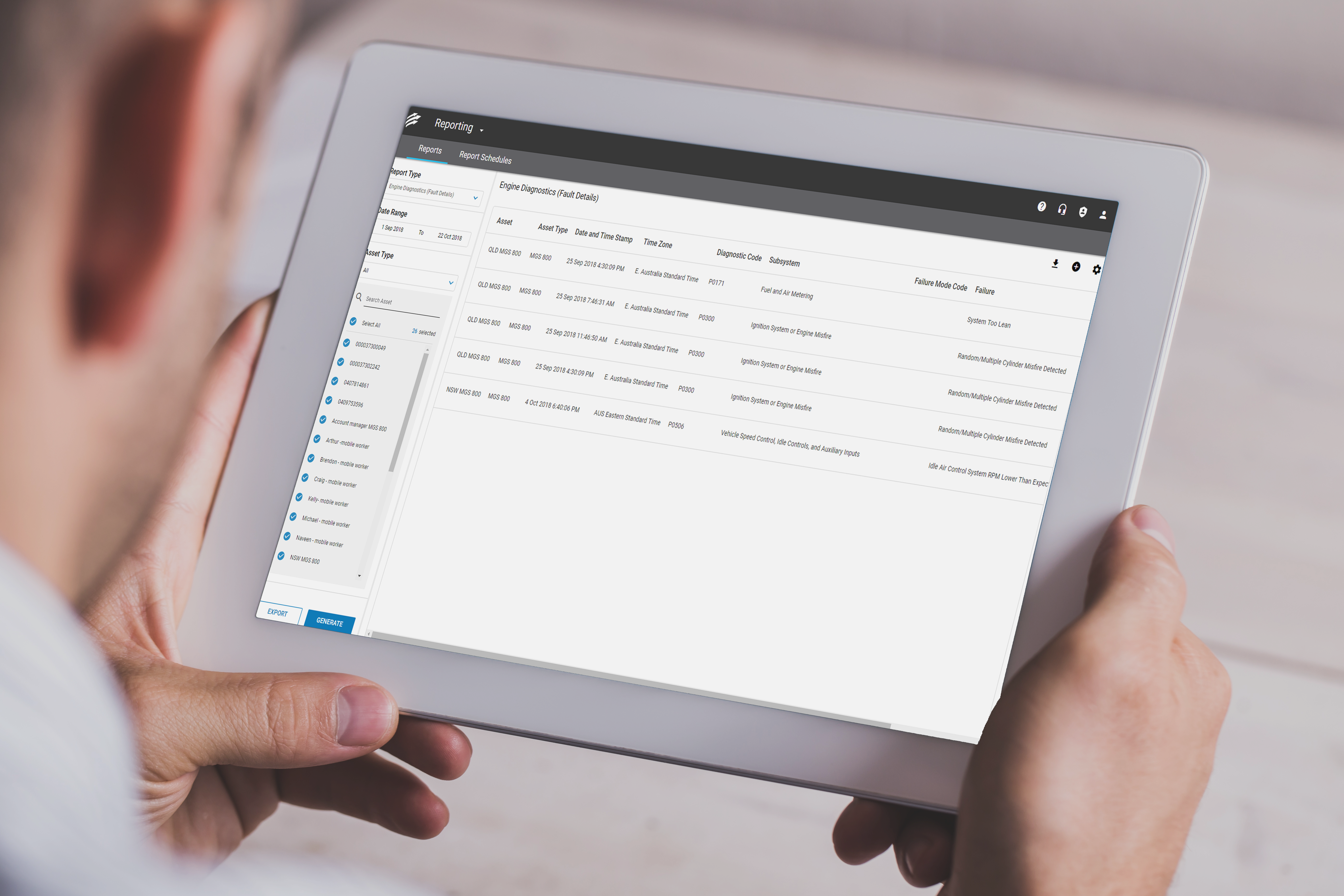

Detailed fault reports

First and foremost, you’ll want the ability to run a report at the touch of a button that will tell you how your fleet health is going. This may feed into and improve your existing fleet monitoring routine, whether it be weekly or monthly, enabling you to better identify which vehicles need attention. Far more accurate than a visual inspection, this report gives you visibility into those often-hidden faults.

Fleet Tracker, a Fleet Complete connected platform, not only analyses overall vehicle health, but also provides advanced diagnostics to help assess specific issues. It means that you can rely on the root cause to be resolved quickly.

On-screen alerts

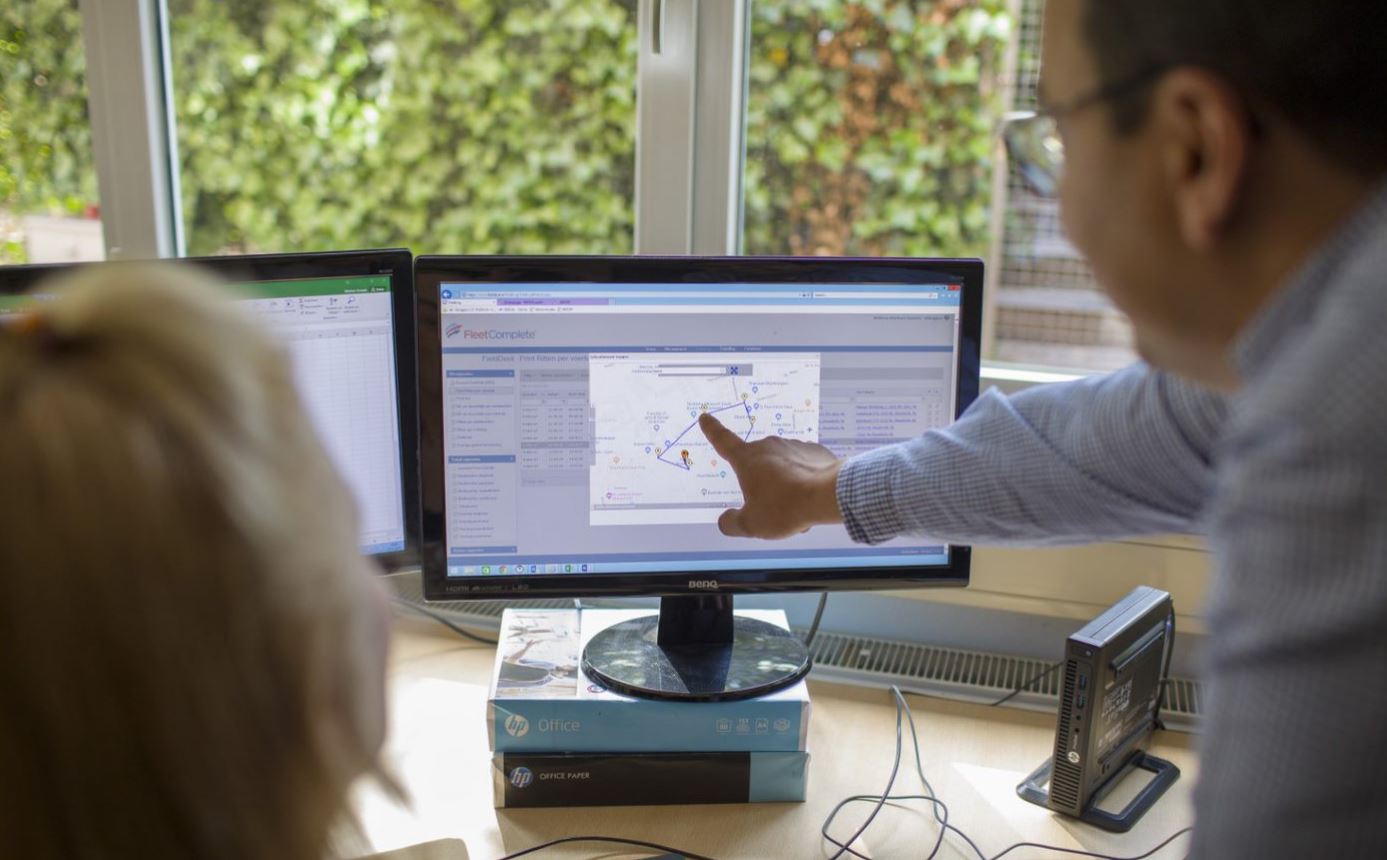

Running a report is handy, but it doesn’t alert you to a potentially urgent situation instantly—instead, it relies on you running the report as part of your maintenance schedule. That’s where on-screen alerts come into play. These are real-time notifications that tell you, instantly, when something is not right.

Any good fleet management software includes this feature. What’s more, it combines with diagnostic features to communicate the extent and urgency of the problem. Using a graded scale, it can tell you if something needs an immediate repair or replacement before the next time the vehicle is on the road, or whether it is something to flag at your next routine vehicle service. In a busy operations environment, this insight is crucial to ensure vehicle health and driver safety, without compromising on fleet up-time.

Proactive, not reactive, problem solving

For certain issues, preventative maintenance is key. Fleet management software like Fleet Tracker is able to tell you about those things that can easily slip your mind, but have serious consequences.

Take your battery, for example. Fleet Tracker will be able to tell you when the charge is beginning to wane, even if it’s not immediately obvious when your driver turns on the ignition. This advanced notice means that you’ll have the information needed to prompt a replacement, rather than risking a flat battery at an inconvenient time.

Quick, hassle-free fixes

Have you ever stopped to think about how, once a problem is identified, you can streamline the fixing procedure? Fleet Tracker has.

Fleet Tracker assigns your fault a special engine code. All that you have to do is pass that code on to the mechanic, who will have the full picture of the issue and be able to order in parts as needed.