With heavy goods vehicles (HGVs) and heavy machinery all operating at once, managing a mine site is a complex job. Whether it’s keeping drivers safe or ensuring assets are as productive as possible, the right tools and practices can make all the difference to your business.

In this article, we will take a closer look at how telematics can provide positive ROI for mine sites that need full asset visibility, better efficiency, and safer working conditions.

An Industry on the Uptick

Things are picking up in the Australian mining industry with robust metal prices and increasing demand. Companies that are quick to take advantage of the 2021 mining boom will profit.

Mining is on the uptick again in Australia. (Image Source)

The focus on mining is on the bottom line, which means there is a strong need for managers to focus on using technologies that drive efficiency and cost savings.

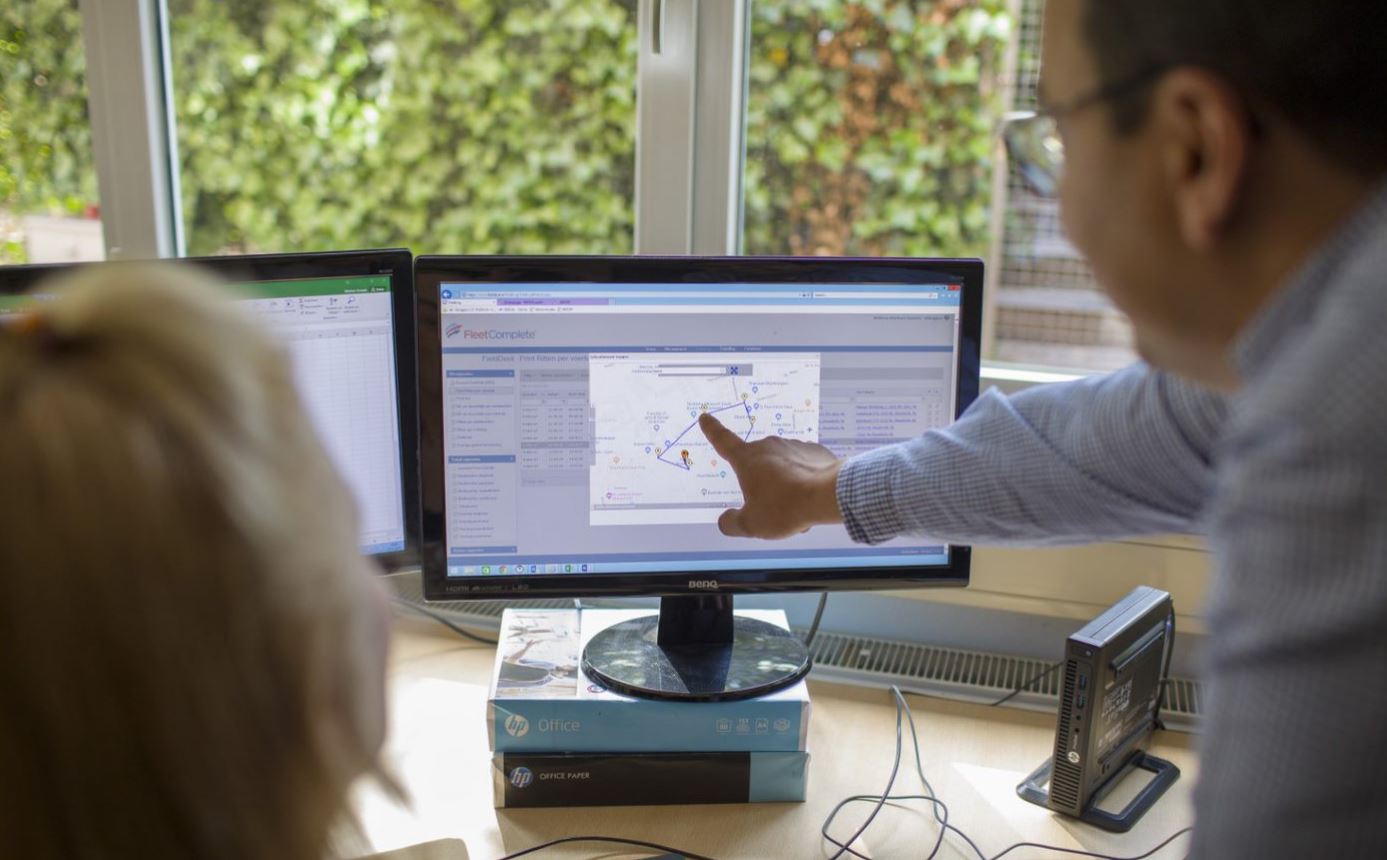

Developments in technology have generated significant value for mine operators. Telematics and fleet management software are becoming increasingly popular ways to gather data that helps managers assess fuel efficiency, driving behaviour, and maintenance costs. These insights can help managers better utilise their assets – so when demand rises, they will be able to get more out of what they have.

“The application of GPS and improvements in communication technologies have made FMS (fleet management systems) considerably more spatially aware and accurate during the early part of the 2000s,” says Peter Johnson, managing director and chief executive officer of Maptek. “As a result, FMS were able to become more specific about material types, locations, and vehicle interactions. Early FMS have been largely superseded by far more advanced communications technology and equipment integration, allowing automated collection of data such as machine health, load state, material type and quantity, location, task, and more.”

Run a Safer Fleet

It’s best to be as proactive as possible when it comes to running a safe fleet – especially in the mining industry where plenty of heavy and potentially dangerous equipment and vehicles operate.

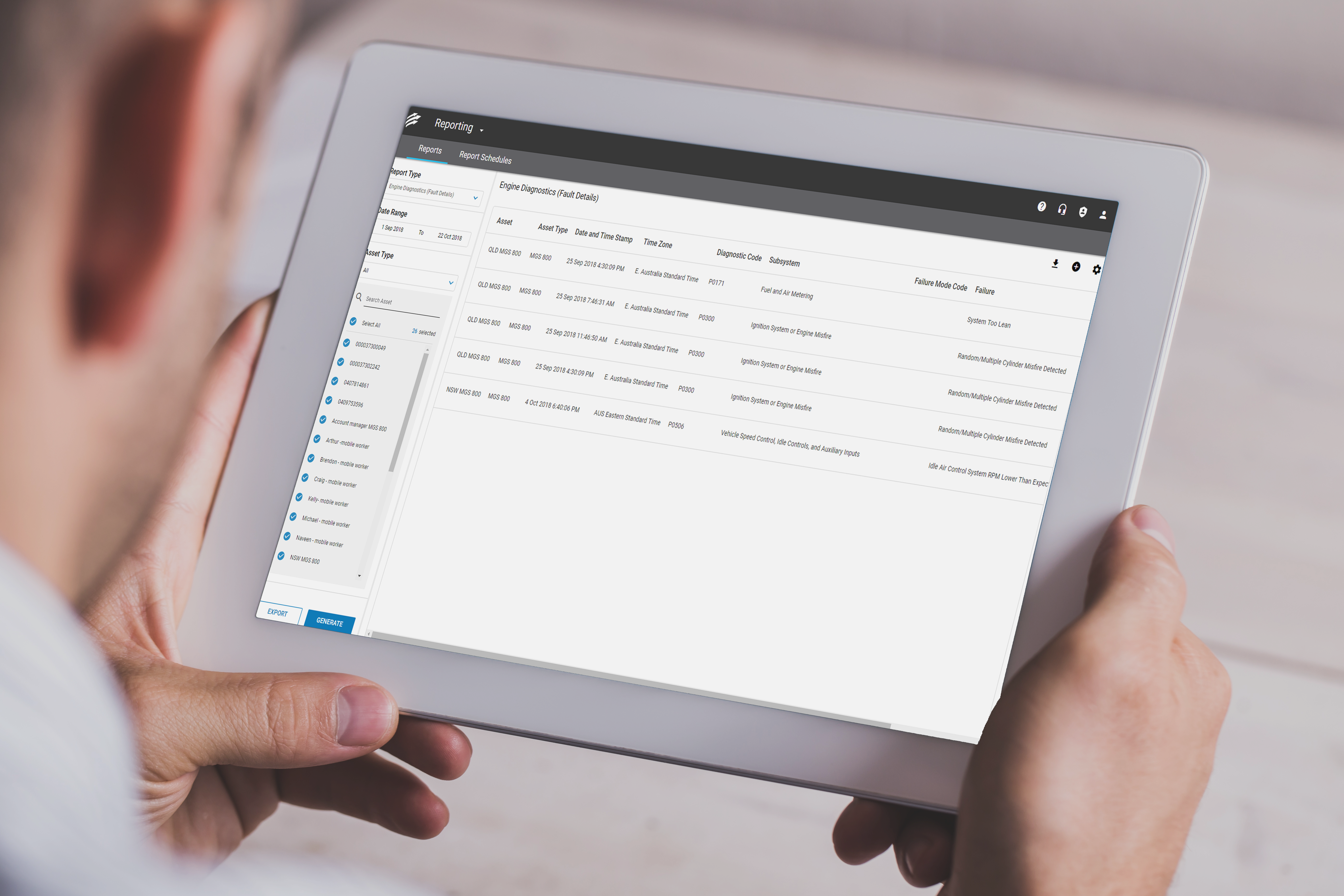

Information about driving habits, equipment location, and vehicle health can help managers accurately identify weaknesses and problems to take action. With telematics and fleet management software, managers can monitor the following:

- Motoring speeds

- Vehicles entering hazardous areas

- Harsh driving

- Maintenance reports on vehicles and equipment

- Assets being operated out of hours or leaving their designated area

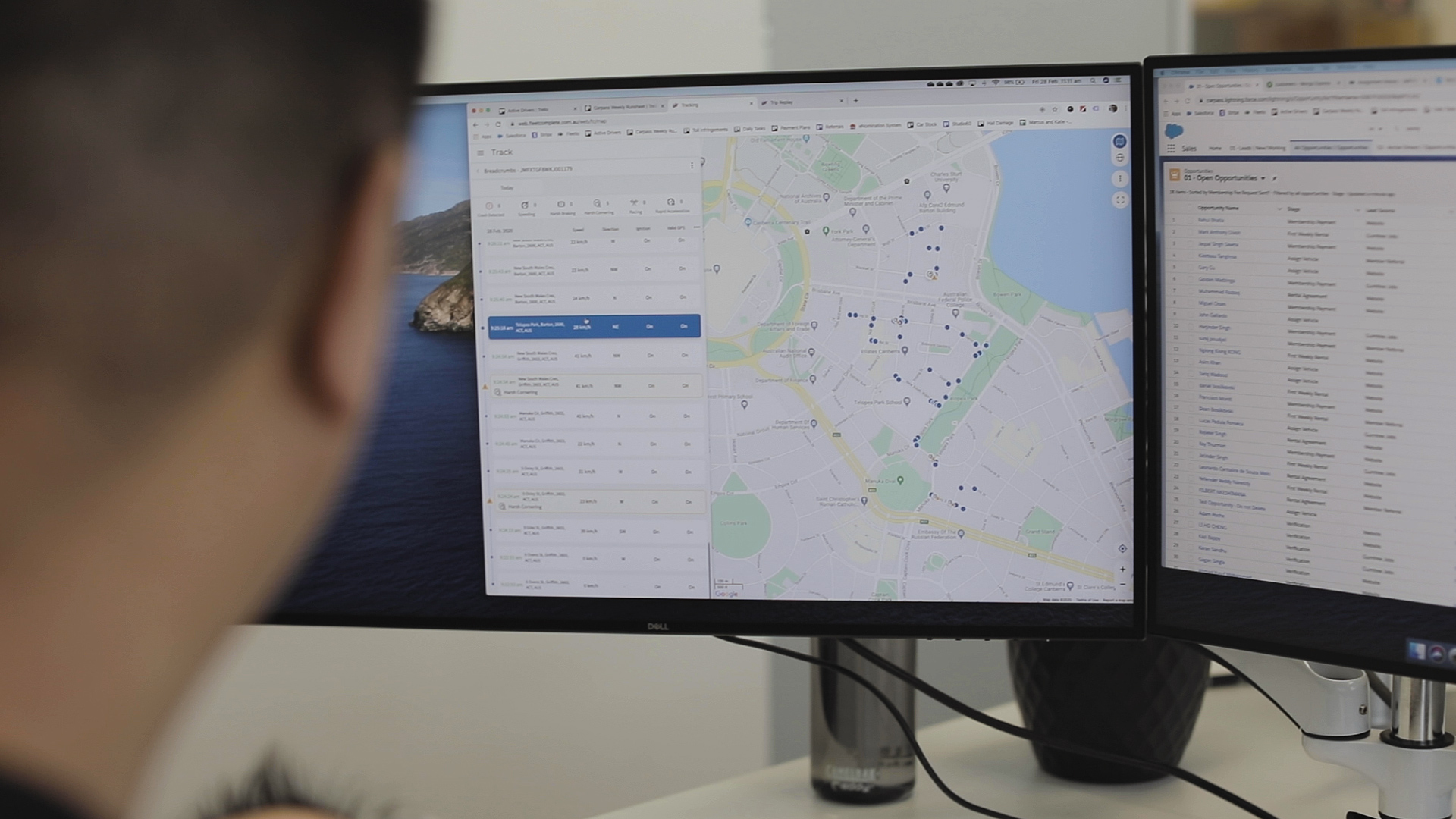

Specifically, Fleet Complete’s Fleet Tracker solution provides this detailed visibility of your fleet. With the ability to receive data and insights in real-time, you can ensure your team and fleet are staying safe in the field, no matter where you are located.

Maximise Asset Use

Mine sites are chock-full of vehicles and equipment, including drills, air compressors, and rolling stock – often all working simultaneously.

While staying on top of these assets may seem difficult, asset trackers are a huge help. These lightweight devices securely attach to any piece of equipment, and once in place, they transmit data back to HQ in real time, allowing managers to do the following:

- See available resources in real time and plan their use accordingly

- Track assets and pinpoint their exact location from one central hub

- Use built-in sensors to monitor temperature and humidity

One example of where this technology can come in handy on a mine site is tracking mobile light towers. This equipment can be a costly resource when staff needs to visit and manually check each one – not to mention a potential safety hazard if they aren’t functioning properly.

This is where asset trackers come in. With the ability to monitor your mine’s mobile light towers remotely, you can ensure they are running up to par by keeping constant tabs on their condition, including fuel levels, light status, and engine information.

Introducing Fleet Complete’s AT1 Asset Tracker

Our AT1 Asset Tracker provides accurate insight into your high-value assets in the field. You can locate and check the status of equipment, tools, and more – all from your smartphone or computer. Small and sturdy, this convenient tracker offers the following:

- 24/7 real-time tracking of equipment, including lighting towers, vehicles, and other mining machinery

- Quick and easy installation

- Built to withstand rugged environments, including water and dust resistance

- Equipped with many sensors including GPS, temperature, humidity, light, and impact

Whether it’s helping to keep drivers safe or ensuring assets are as productive as possible, the right tools can make all the difference to your business.

We’re Here to Help

To thrive in 2021 and beyond, mining companies need to reap the benefits technology has to offer. Beyond the safety of your drivers, equipping your fleet with fleet management tools helps improve efficiency and take advantage of the flourishing mining industry.

Fleet Complete’s experts are on hand to help your mining fleet operate smoothly. From activating and installing new devices to discussing the best options for your operations – we’re here to help ensure you get the most out of your fleet management technology. Get started today by trying out our Fleet Complete demo.

If you found this article helpful, please share it on social media.